Applications

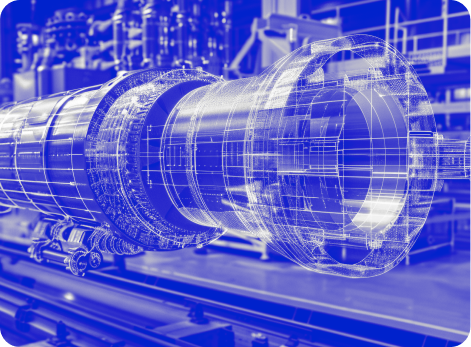

Stainless Steel Tube Solutions for the Energy Sector

Stainless steel pipes are essential in the energy sector, offering durability under high heat, pressure, and corrosive environments. Their thermal stability and low maintenance needs make them a preferred choice.

Why Stainless Steel?

- Withstands 200–600°C and high-pressure conditions

- Low thermal expansion reduces leak risks

- Superior corrosion resistance for long-term reliability

Key Applications

- Heat exchangers

- Steam & thermal transfer lines

- Condensers & cooling systems

Advantages

- Low maintenance: No coating or repainting needed

- Longer service life than carbon steel

- Higher energy efficiency with smooth internal surfaces

Stainless Steel Pipes & Profiles for the Automotive Industry

Stainless steel pipes are widely used in the automotive industry for their strength, corrosion resistance, and clean finish. They offer long-lasting performance in both structural and visible components.

Why Stainless Steel?

- Corrosion-resistant: Ideal against road salt, moisture, and harsh conditions

- Heat & vibration tolerant: Reliable under engine and exhaust system stress

- Aesthetic: Polished surfaces add value and visual appeal to exterior parts

Key Applications

- Exterior protection systems (bull bars, rear bars)

- Exhaust systems

- Fuel and emission lines

- Roll cages & chassis reinforcements

Advantages

- Lightweight yet strong: Improves fuel efficiency

- Easy to form & weld: Ideal for complex designs

- Low maintenance: No painting or coating needed

Stainless Steel Pipes for Greenhouse & Irrigation

Stainless steel pipes are ideal for modern agriculture, offering durability, corrosion resistance, and low maintenance in water-intensive systems like greenhouses and pressurized irrigation.

Why Stainless Steel?

- Resists UV, moisture, and outdoor conditions

- Withstands impact and vibration

- Smooth interior ensures clog-free water flow

Key Applications

- Fogging and Misting systems

- Pressurized irrigation

- Greenhouse piping

Advantages

- Longer lifespan than plastic or galvanized options

- Easy to install and connect to existing systems

- Lower maintenance, better performance

Stainless Steel Pipes in Industrial Facilities

Stainless steel pipes are widely used in industrial systems for their leak-proof performance, pressure resistance, and long service life.

Why Stainless Steel?

- Handles pressure and temperature changes without deformation

- Resists moisture, steam, and airborne chemicals

- Smooth interiors improve flow and ease cleaning

Key Applications

- Process lines

- Equipment piping

- Tank & filling systems

- White goods

Advantages

- 10–20 years of service life

- Leak-tight, safe connections

- Lower maintenance, reduced downtime

Stainless Steel Pipes for the Food & Beverage Industry

In the food and beverage industry, hygiene, corrosion resistance, and material traceability are essential. Stainless steel pipes meet these demands, ensuring safe transport of liquids and gases in clean environments.

Why Stainless Steel?

- Non-reactive and hygienic

- Corrosion-resistant

- Smooth internal surfaces

Key Applications

- Process piping

- CIP (Clean-in-Place) systems

- Tank and equipment connections

Advantages

- Fully traceable materials with certification

- Compatible with food-grade standards

- Long service life with minimal maintenance

Precision and Scale Through Automated Production

Bright Annealing Line

Cut to Length

Quality Lab

Insights from the Stainless Steel Experts

What Is Annealing and Why Does It Matter?

Read More →

TIG vs. Laser Welding: A Technical Comparison

Read More →

Meeting European Tube Standards: EN 10217-7...

Read More →Certified Excellence

→ EN 10217-7:2001

→ EN 10296-2:2005/AC:2007

→ ISO 14001:2015

→ ISO 45001:2018

→ ISO 9001:2015

→ AD 2000 W0

→ PED Annex I sec. 4.3

→ EN 764-5

reports on request