Stainless Steel Pipes Built to European Standards

With 6,000,000 meters of stainless steel pipes produced annually, STS is Europe’s trusted supplier for high-performance TIG-welded solutions.

Serving

Europe

and Asia

and Asia

100%

Quality Control

Certified

to EN 10217-7, AD 2000 W0 & others

Advanced

Annealing Line Operational

Discover our precision-engineered stainless steel tube solutions:

Why Choose STS

Certified manufacturing to European and international standards

Whether you need a custom prototype batch or a full-scale production run, our lines adapt to meet your capacity and timeline.

100% dimensional and surface

quality control

Our processes are fully compliant with EN 10217-7, ASTM A554, and ISO 9001 to ensure quality, traceability, and global compatibility.

Flexible production for low and high-volume orders

Every tube undergoes rigorous inspection for tolerance, straightness, surface finish, and weld integrity — no batch leaves unchecked.

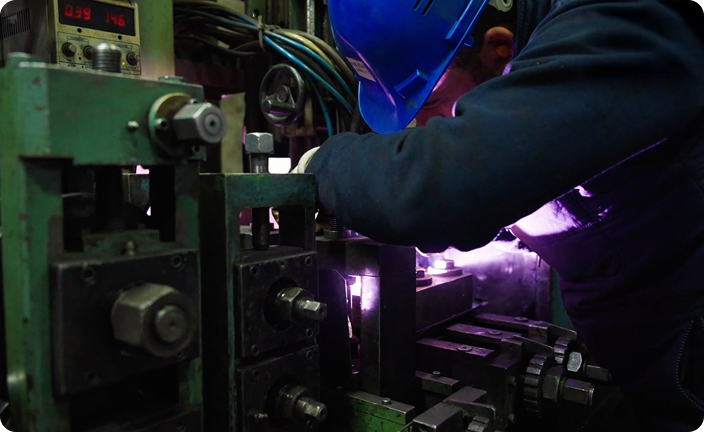

Decades of expertise in TIG welding precision tubing

Our team brings years of hands-on experience in producing high-precision stainless steel pipes for critical industrial applications.

Built for performance across industries

Explore Applications →Automotive

Engineered for strength and precision, our stainless steel pipes are ideal for automotive applications such as crash bars and exhaust systems, where durability, corrosion resistance, and aesthetic finish are essential.

Energy

From heat exchangers to solar thermal systems, STS pipes ensure optimal thermal conductivity and long-term performance under high-pressure and high-temperature conditions.

Agriculture

In greenhouse and irrigation systems, our precision-welded pipes support efficient misting and fluid distribution with exceptional corrosion resistance and dimensional stability.

Industrial

For corrosive environments in chemical processing, STS pipes deliver safe, reliable fluid transport thanks to high-grade materials and certified welding integrity.

Food & Beverage Industry

In the food and beverage industry, hygiene, corrosion resistance, and material traceability are essential. Stainless steel pipes meet these demands, ensuring safe transport of liquids and gases in clean environments.

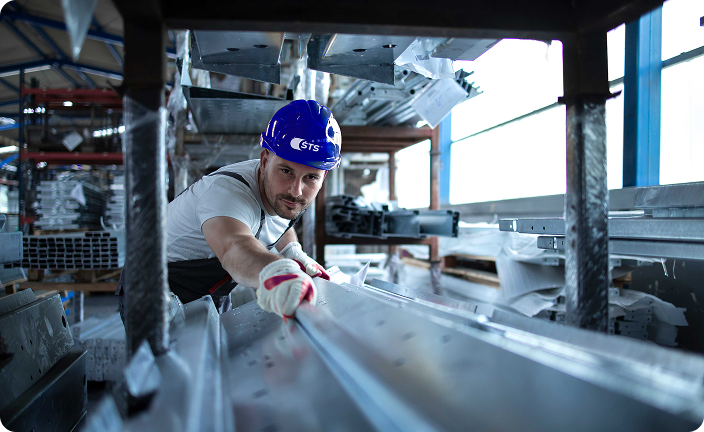

Precision and Scale Through Automated Production

Bright Annealing Line

Cut to Length

Quality Lab

Insights from the Stainless Steel Experts

Meeting European Tube Standards: EN 10217-7

Read More →

TIG vs. Laser Welding: A Technical Comparison

Read More →

What Is Annealing and Why Does It Matter?

Read More →Certified Excellence

→ EN 10217-7:2001

→ EN 10296-2:2005/AC:2007

→ ISO 14001:2015

→ ISO 45001:2018

→ ISO 9001:2015

→ AD 2000 W0

→ PED Annex I sec. 4.3

→ EN 764-5

reports on request