Stainless Steel Profiles

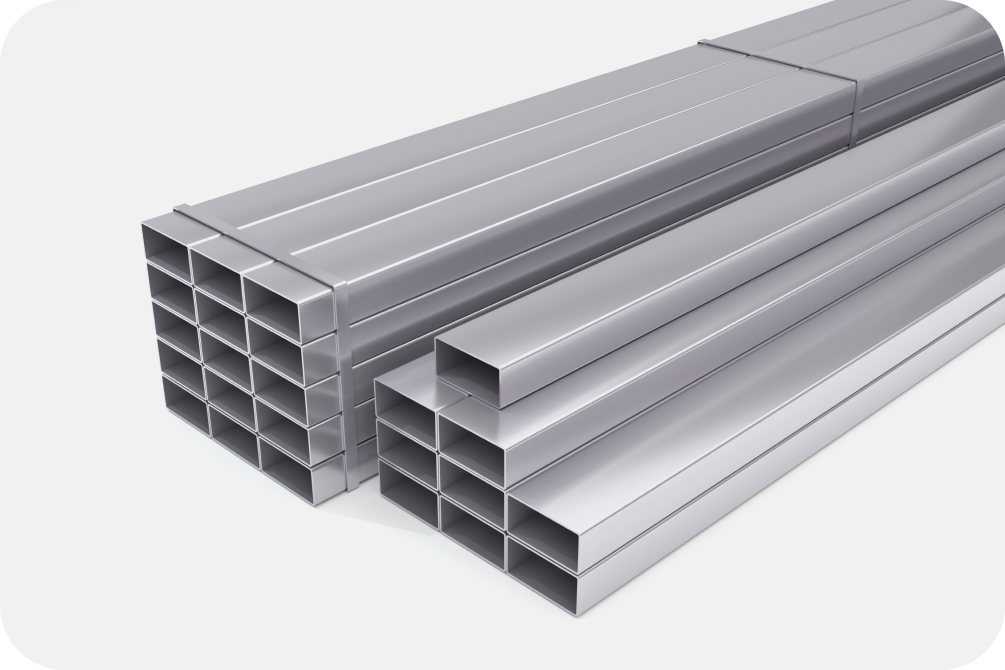

| Diameter (mm) |

Thickness (mm) | ||||

|---|---|---|---|---|---|

| 0.80 | 1.00 | 1.20 | 1.50 | 2.00 | |

| 10×20 | 0.365 | 0.451 | 0.535 | 0.657 | |

| 10×30 | 0.493 | 0.611 | 0.727 | 0.898 | |

| 10×40 | 0.776 | 0.925 | 1.146 | ||

| 10×50 | 1.106 | 1.371 | |||

| 15×15 | 0.365 | 0.451 | 0.535 | 0.657 | |

| 15×20 | 0.425 | 0.526 | 0.625 | 0.770 | |

| 15×25 | 0.611 | 0.727 | 0.898 | ||

| 15×30 | 0.676 | 0.805 | 0.995 | ||

| 15×40 | 0.851 | 1.016 | 1.258 | ||

| 15×50 | 1.238 | 1.536 | |||

| 20×20 | 0.493 | 0.611 | 0.727 | 0.898 | 0.851 |

| 20×25 | 0.676 | 0.805 | 0.995 | 1.002 | |

| 20×30 | 0.625 | 0.776 | 0.925 | 1.146 | 1.172 |

| 20×40 | 0.926 | 1.106 | 1.371 | 1.302 | |

| 20×50 | 1.102 | 1.316 | 1.634 | 1.653 | |

| 25×25 | 0.625 | 0.776 | 0.925 | 1.146 | 2.023 |

| 25×30 | 0.851 | 1.016 | 1.258 | 1.172 | |

| 25×40 | 1.037 | 1.238 | 1.536 | 1.302 | |

| 25×50 | 1.184 | 1.415 | 1.758 | 1.502 | |

| 30×30 | 0.745 | 0.926 | 1.106 | 1.371 | 1.803 |

| 30×40 | 0.885 | 1.102 | 1.316 | 1.634 | 2.153 |

| 30×50 | 1.247 | 1.490 | 1.852 | 1.502 | |

| 40×40 | 1.247 | 1.490 | 1.852 | 1.653 | |

You May Also Like

FAQ

What’s the difference between TIG welded and laser welded stainless steel pipes?

TIG welded pipes are produced using Tungsten Inert Gas welding, providing excellent control, clean seams, and strong mechanical properties. They are ideal for applications requiring aesthetic appearance and superior corrosion resistance.

Laser welded pipes, on the other hand, use focused laser beams for ultra-narrow weld seams, allowing high-speed production with minimal heat distortion. This method is suited for high-volume, precision-driven manufacturing.

What is the minimum order quantity (MOQ)?

Our minimum order quantity varies depending on the product type, dimensions, and stainless steel grade. Standard production typically starts from one production batch, but we also accommodate smaller project-based quantities upon request. Contact us with your specifications and we will provide an exact MOQ for your order.

What are the standard delivery times?

Typical delivery times range from 2 to 6 weeks, depending on product complexity, material grade availability, and order volume. Custom or non-standard profiles may require additional processing time. We always provide a precise delivery schedule during the quotation process to help you plan your project efficiently.

Do you offer cut-to-length stainless steel pipes?

Yes. We provide custom cut-to-length services to meet specific installation or production requirements. Pipes and profiles can be cut with high precision according to your measurements, helping you reduce waste and streamline assembly on-site.

Are your stainless steel pipes certified?

Absolutely. Our products comply with leading European and international standards, including EN 10217-7, EN 10296-2, ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, and additional certifications upon request. Full inspection reports and material certificates are available to ensure traceability and technical reliability.

Which stainless steel grades do you offer?

We manufacture pipes, profiles, and special shapes in a wide range of stainless steel grades, most commonly 304, 304L, 316, and 316L, as well as other grades depending on mechanical or corrosion-resistance requirements. If your project requires a specific alloy, our team will help you determine availability and suitability.

Can I get technical support when choosing the right product?

Yes. Our engineering and sales teams provide personalized technical support to help you select the optimal stainless steel solution based on application, load requirements, environment, and industry standards. Whether you need pipes, standard profiles, or custom-engineered shapes, we’re here to assist you at every step.